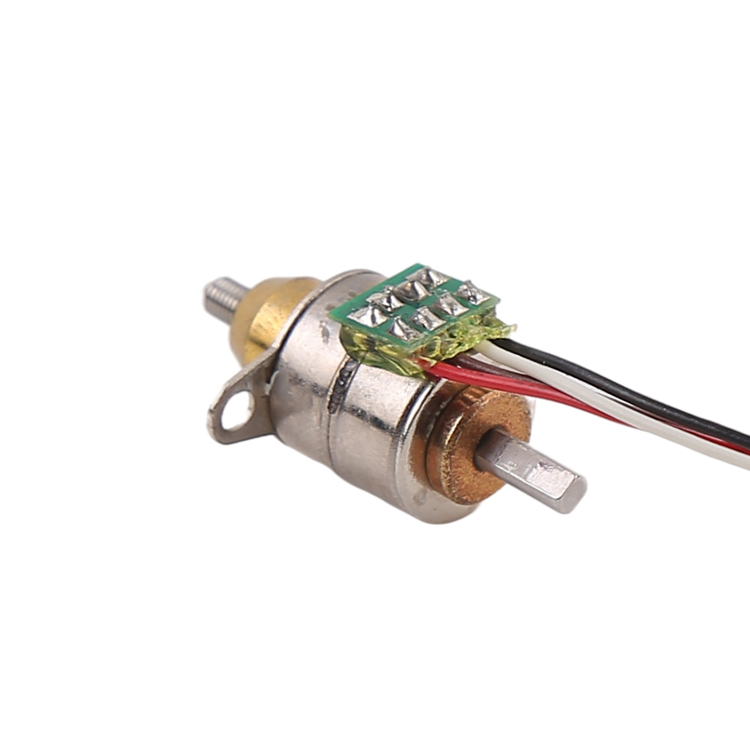

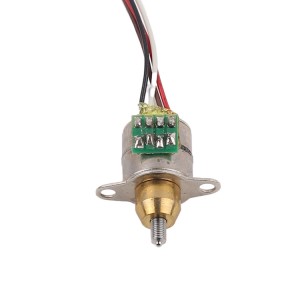

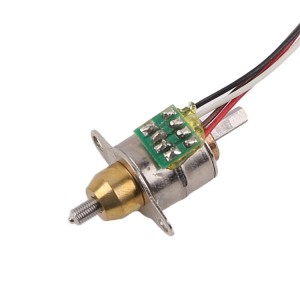

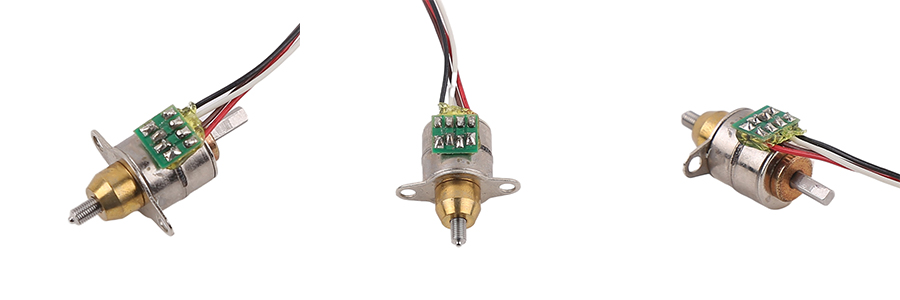

10 mm lineêre motor met loodskroef-stapmotor met anti-rotasiebeugel

Beskrywing

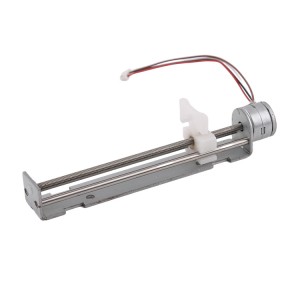

Die SM10 lineêre motor is 'n spesiale lineêre motor van ons maatskappy, 'n stapmotor met 'n loodskroef met 'n anti-rotasiebeugel. 'n Rotor met 'n moer, die loodskroef beweeg vorentoe of terug soos die rotor kloksgewys of antikloksgewys draai.

Dit skakel die rotasie van die motor om in 'n lineêre beweging deur die relatiewe beweging van die binneste rotor en die skroef.

Die motor het 'n staphoek van 18 grade.

Die afstand tussen die loodlyne is 1 mm.

Die lengte van die verbindingsdraad kan volgens die kliënt se vereistes aangepas word.

Hoofsaaklik gebruik in klepbeheer, outomatiese knoppies, mediese toerusting, tekstielmasjinerie, drukkers, robotte en ander verwante velde.

Bedryfstemperatuur: -40°C - 60°C

Motorrigting. Met die klok en teen die klok

Indien u belangstel in ons produkte, stuur asseblief vir my 'n e-pos.

Parameters

| Model Nr. | SM10 lineêre stapmotor |

| Dryfspanning | 5V GS |

| Spoelweerstand | 10Ω±7%/fase |

| Aantal fases | 2 fases |

| Staphoek | 18°/stap |

| Opwekkingsmetode | 2-fase opwekking |

| Rymodus | Bipolêre aandrywing |

| Uittrek-stootkrag | Meer as 60 gf teen 500 PPS |

| Maksimum reaksiefrekwensie | Meer as 1200 PPS |

| Maksimum aanvangsfrekwensie | Meer as 1200 PPS |

| Isolasieklas | Klas e vir spoele |

| Isolasiesterkte | 100V wisselstroom vir een sekonde |

| Isolasieweerstand | 50mΩ GS 500V |

| Bedryfstemperatuurreeks | -0~+55℃ |

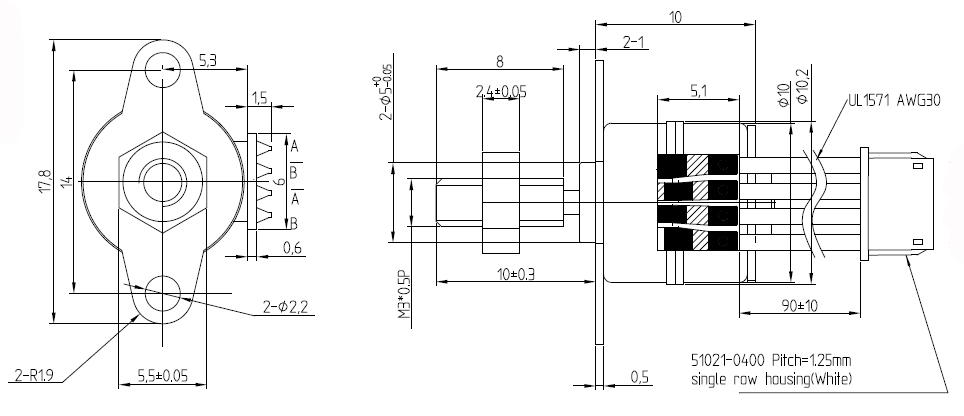

Ontwerptekening

Toepassing

Die motor se spoed word bepaal deur die dryffrekwensie, en dit het niks met die las te doen nie (tensy dit stappe verloor).

As gevolg van die hoë-presisie spoedbeheer van stapmotors, kan jy met 'n drywer-beheerde stap baie presiese posisionering en spoedbeheer bereik. Om hierdie rede is stapmotors die motor van keuse vir baie presisie bewegingsbeheer toepassings.

Vir lineêre stapmotors word hulle wyd gebruik in:

Mediese toestel

Kameratoerusting

Klepbeheerstelsel

Toetsinstrument

3D-drukwerk

CNC-masjien

en so aan

Pasmaakdiens

Die ontwerp van die motor kan aangepas word volgens die kliënt se vereistes, insluitend:

Motor se deursnee: ons het 'n motor met 'n deursnee van 6 mm, 8 mm, 10 mm, 15 mm en 20 mm

Spoelweerstand/gegradeerde spanning: spoelweerstand is verstelbaar, en met hoër weerstand is die motor se gegradeerde spanning hoër.

Beugelontwerp/loodskroeflengte: as die klant wil hê dat die beugel langer/kort moet wees, met spesiale ontwerp soos monteringsgate, is dit verstelbaar.

PCB + kabels + konnektor: PCB se ontwerp, kabellengte en konnektorhoogte is alles verstelbaar, hulle kan in FPC vervang word indien kliënte dit benodig.

Leweringstyd en verpakkingsinligting

Leweringstyd vir monsters:

Standaardmotors in voorraad: binne 3 dae

Standaardmotors nie in voorraad nie: binne 15 dae

Gepasmaakte produkte: Ongeveer 25~30 dae (gebaseer op die kompleksiteit van die aanpassing)

Leidingstyd vir die bou van 'n nuwe vorm: gewoonlik ongeveer 45 dae

Leweringstyd vir massaproduksie: gebaseer op bestelhoeveelheid

Verpakking:

Monsters word in 'n skuimspons met 'n papierboks verpak, per ekspresse gestuur

Massaproduksie, motors word in geriffelde kartonne met deursigtige film buite verpak. (versending per lug)

Indien per see gestuur, sal die produk op palette verpak word

Versendingsmetode

Vir monsters en lugversending gebruik ons Fedex/TNT/UPS/DHL.(5~12 dae vir ekspresdiens)

Vir seevervoer gebruik ons ons verskepingsagent en word vanaf die hawe van Sjanghai gestuur.(45~70 dae vir seevervoer)

Gereelde vrae

1. Is jy 'n vervaardiger?

Ja, ons is 'n vervaardiger, en ons produseer hoofsaaklik stapmotors.

2. Waar is jou fabrieksligging? Kan ons jou fabriek besoek?

Ons fabriek is geleë in Changzhou, Jiangsu. Ja, u is baie welkom om ons te besoek.

3. Kan jy gratis monsters verskaf?

Nee, ons verskaf nie gratis monsters nie. Kliënte sal nie gratis monsters regverdig behandel nie.

4. Wie betaal vir die versendingskoste? Kan ek my versendingsrekening gebruik?

Kliënte betaal vir die versendingskoste. Ons sal u die versendingskoste kwoteer.

As jy dink jy het 'n goedkoper/geriefliker versendingsmetode, kan ons jou versendingsrekening gebruik.

5. Wat is jou MOQ? Kan ek een motor bestel?

Ons het nie MOQ nie, en jy kan slegs een stuk monster bestel.

Maar ons beveel aan dat u 'n bietjie meer bestel, ingeval die motor tydens u toetsing beskadig word, en u 'n rugsteun kan hê.

6. Ons ontwikkel 'n nuwe projek, bied julle 'n pasmaakdiens? Kan ons 'n geheimhoudingsooreenkoms teken?

Ons het meer as 20 jaar ondervinding in die stapmotorbedryf.

Ons het baie projekte ontwikkel, ons kan volledige aanpassings van ontwerptekening tot produksie bied.

Ons is vol vertroue dat ons jou 'n paar raad/voorstelle vir jou stapmotorprojek kan gee.

As jy bekommerd is oor vertroulike kwessies, ja, ons kan 'n NDA-kontrak teken.

7. Verkoop julle drywers? Produseer julle hulle?

Ja, ons verkoop wel drywers. Hulle is slegs geskik vir tydelike monstertoetse, nie geskik vir massaproduksie nie.

Ons produseer nie drywers nie, ons produseer slegs stapmotors